In accordance with the Work Health and Safety Act (the WHS Act), there is a duty to provide a safe place of work. The highest risk relating to roof work is from falls from Height. The Code of Practice -Managing the Risk of Falls at Workplaces was approved by the ministerial council as an approved Code of Practice for compliance with the WHS Act which came into force in January 2012.

Construction Planning

The first steps to managing risks are to identify them.

In accordance with the “Hierarchy of Control” the obligation is to eliminate or minimise the risk where possible. The Code of Practice states that work at height should be avoided where possible. This may involve proposing an alternative specification to the Design Team which may avoid some work at roof level. The Design team are under an obligation to consider the safety of Installation under their duties to the WHS Act.

If an alternative specification does not reduce the amount of work to be undertaken at height then methods of work to reduce the time spent at height for the specification proposed must be considered. This may involve prefabricating some of the components at ground level and loading them into position as prefabricated units.

The Rossway Safeway Roof Safety Protection System

The Rossway Safeway Roof Safety Protection System is a roof safety protection system designed and developed to provide fall protection during roofing installation.

The Rossway Safeway system provides fall protection to the “leading edge”; the open edge that is presented when roof panels are laid in a tier fashion. It also provides protection to the “working edge” the area that is exposed to a fall when the leading edge protection is moved by the tier width of the panel being installed.

The system consists of a platform, which is made of extruded aluminium and available in various lengths from 3m to 8m long and is joined together to provide any combination of roof slope length; to this platform an integral toe board is installed and double edge handrail to the leading edge. The platform is moved along the purlin length with a purpose designed roof trolley system (a video sequence of the system in use can be view by clicking here). On to the platform system a working edge protection system is installed to the exposed edge opposite to the leading edge where the handrail is installed. The working edge protection system consists of an aluminium framework which fits between the purlin spacing and is adjustable to suit varying purlin centres, the framework provides fall protection to the open gap presented when the system is moved the module width of the roof installation. The working edge protection is attached to the platform and therefore moves as the platform system is moved. This means that the roof installation can be installed unimpeded and the roof operative is protected from a fall via fall protection means (as opposed to fall arrest).

The Rossway Safeway system can be used as the primary means of fall protection for installing many types of roof construction.

Composite roof panels. In the case of Composite roof panels consisting of; an inner metal prefinished internal skin, an insulation core and an external profiled metal outer skin. All these components are manufactured off site and the panel comes to site as a factory formed composite unit. Because the internal skin is a prefinished metal finish it may be inappropriate to install roof mesh which will spoil the aesthetics of the internal facade. In this instance the Rossway Safeway system will provide fall protection for the installation of the roof panel.

Removal of existing multi layer roof constructions. In multi-layer roof constructions such as built up roof construction with inner layer of wire mesh, insulation quilt, and outer roof sheeting, there have been concerns regarding the capability of the roof mesh to provide safety at the end of the roof service life. The mesh may have corroded and deteriorated and not offer fall protection. In this instance the Rossway Safeway system can be used to provide fall protection when removing existing fragile roof components.

Installing new multi layer roof constructions. In order to install the roof layers including the initial roof mesh which is the first layer to be installed, the Rossway Safeway system can be utilised to provide safe means of access to undertake this operation.

Training and Certification to use the Rossway Safeway Roof Safety Protection system

Operatives that use the Rossway Safeway system can receive training from the registered training organisation Height Safety Engineers. A full size training facility has been constructed inside the training facility and enables operatives to learn all the issues relating to the installation and safe use of the Rossway Safeway system. The operative will gain a certificate of competence upon successful completion of the course. This ensures that operatives using the Rossway Safeway system are certified as competent to use it and understand all the issues relating to safe fall protection during roof installation.

The training facility provides a safe controlled environment where operatives can learn how to safely install and use the Rossway Safeway System

The training facility provides a safe controlled environment where operatives can learn how to safely install and use the Rossway Safeway System

The Use of Fall Arrest Harnesses for Roofing Operations

As has been identified in The hierarchy of Control the last resort is to arrest the fall. If this is the option to be considered, it must be clear that the other options of removing the risk or protecting the operative from falling have been considered and cannot be implemented. The operation of arresting a fall, allows the operative to fall and attempts to minimise the effect of the fall. As such there is a possibility of injury to the operative being arrested in the fall, but fall arrest, if correctly used, should reduce the injury rather than allowing the fall to occur without arrest.

If considering the fall arrest harnesses for any work at height then guidance is provided in the Code of Practice Managing Risk of Falls at Workplaces )

If considering Fall Arrest Harnesses there are a number of important considerations:-

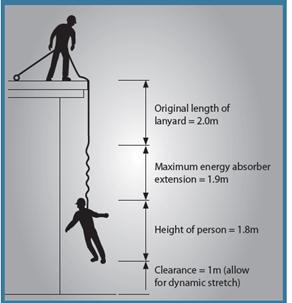

- Limitation of Fall Distance The diagram indicates that in this scenario the minimum fall distance would be 6.7m. Therefore if the roof was less than 6.7m from the floor then use of harnesses would not be an option.

- Ensure that the effect of “swing down” have been considered. The length of the Landyard must be correctly selected so that swing down does not occur. Roof work operations require movement and mobility at roof level and extended lanyard length. For this reason use of harness for roof work is not a practical option.

- Ensure that the effect of “swing back” has been considered. During “swing back” the length of the lanyard and positioning of the anchor contact may allow the operative to hit the structure which must be avoided.

- Suitable Load tested Anchorage point. All anchorage points must have a capacity to restrain the fall and must be designed and tested for the particular circumstances. Typically, an anchor with the capability to sustain a force of 12kN would be required if only one person could have a limited free fall, this would increase to 15kN for one person where a free fall is possible and 21kN for 2 persons. These are significant forces (21kN equivalent to 2.1 tonne load) which would often be impractical to incorporate as “temporary anchors” for the purpose of installing roofing products over large areas.

- Suspension Intolerance. Suspension Intolerance can occur with fall arrest harnesses when a person has an arrested fall and is suspended in an upright vertical position. This may lead to renal failure and eventually death. For this reason the quick rescue of a person suspended in a harness is vital and the Code of Practice Managing the Risk of Falls at Workplaces see 9.2 suggests that workers should be rescued within 5 minutes of a fall. For this reason it is important that workers do not work alone when using harness fall protection and other operatives at roof level have the correct rescue equipment to hand and are trained to rescue the victim in the event of a fall.

For the reasons noted above the use of fall arrest harnesses for the operation of providing arrest for roofing operations is extremely limited and would often render this solution impractical.

Furthermore it must be appreciated that roof work for industrial/ commercial construction is an operation that is undertaken over a large area in a relatively short space of time. These systems are modular constructions in module widths, usually 1m wide. At full productivity it is common to achieve production rates in the region of 1000 sq.m. per day, with 5 operatives working concurrently. Each operative will need to access the work area, possibly two or three time. What this means is that each operative is covering an area of 2000 sq. m, which if working on module width 1m, is 2 km distance in the working day. For this reason it is impractical to rely on fall arrest devices, such as harness and restraint lines, as a system cannot be devised to cover such large distances for so many operatives. |